-

- News Center

- Related News

-

- Painted color aluminum sheet for ropp caps

- 2015 Haomei Annual Meeting of the New Year

- The painted color alu

-

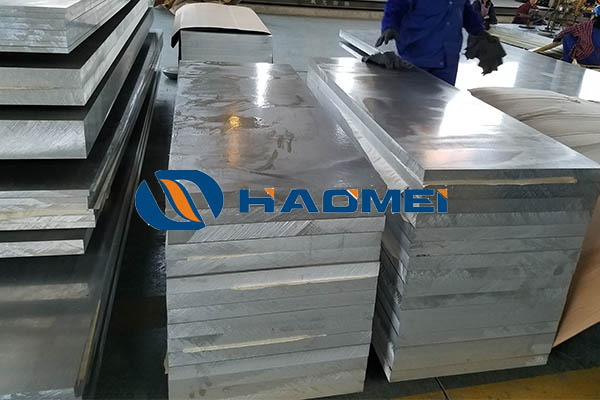

- Common characteristics of 7075 aluminum plate

7075 aluminum plate has an excellent strength much stronger than common steel. Containing zinc, copper and magnesium, it takes the lead in 7000 series of aluminium alloy plates with excellent properties. Among leading 7075 aluminum plate suppliers in China, we share its common characteristics are as below.

7075 aluminum plate is a frequently applied alloy with a wide variety. It contains zinc, copper and magnesium, but it can't be welded, and its corrosion resistance is poor. Many CNC cutting parts are made of 7075 alloy. Zinc is the main alloying element in this series, and a small amount of magnesium alloy allows the material to be heat treated to reach very high strength properties. This series of materials generally add a small amount of copper, chromium and other alloys, which makes its performance reach a top grade featured by the highest strength and good adaptability as a raw material for aircraft frames and high-strength accessories.

7075 aluminum plate is used in the aircraft manufacturing industry in the late 1940s and is still widely used in the aviation industry. It is characterized by good plasticity after solution treatment, particularly good heat treatment strengthening effect, high strength below 150 °C and particularly good low temperature strength. Two-stage aging improves the ability of the alloy to resist stress corrosion cracking. The plasticity in the annealed and quenched state is slightly lower than the same state of 2A12. It is slightly better than 7A04, the static fatigue of the plate is not sensitive, the stress corrosion function is better than 7A04. The 7075 aluminum alloy is generally used for solid solution ten artificial aging treatment, hardness Up to HRB95 or above. In general, 7075 is re-solution hardened after extrusion and artificial aging treatment to provide strength.

- Haomei aluminum

- haomei Aluminium Plate