-

- News Center

- Related News

-

- Painted color aluminum sheet for ropp caps

- 2015 Haomei Annual Meeting of the New Year

- The painted color alu

-

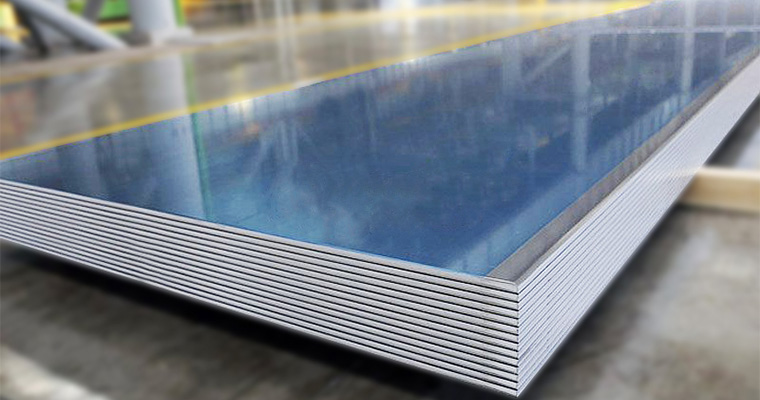

- aluminium 6061 sheets/5052 aluminium sheet plate

Aluminum alloy sheet 5052 slightly higher than the hardness of aluminum 6061 plate , but 6061 alloy composition is more suitable for aerospace use, 6061 aluminum alloy is the most suitable processing state is T651, is based on the 6061 t6 marine aluminum plate stretch, eliminate stress, with excellent processing Performance, good corrosion resistance and weldability, good oxidation and other fine features.

Aluminum alloy sheet 5052 material hardness is higher and the intensity is higher, especially with high fatigue strength, high plasticity and corrosion resistance, heat treatment can not be strengthened, with contact welding and hydrogen soldering good weldability.

5052 aluminum sheet and aluminum 6061 plates are used in the manufacture of ships, but the most widely used in aircraft manufacturing.

The main difference between aluminium 6061 sheets and 5052 aluminium sheet plate:

1. The difference in composition:

Ingredients: 5052 Si, 0.25;Fe, 0.40;Cu, 0.10;Mn, 0.10;Mg, 2.20 2.80;Cr, 0.15 0.35;Zinc, 0.10

6061 alloy composition: Si0.40-0.80;Fe, 0.70;Cu, 0.15 1.40;0.15 0.8, 0.15 Mn, Mg, Cr, 0.04-0.35, zinc, 0.25

2. Performance difference:

aluminum alloy sheet 5052 Performance: Tensile strength: 170-305Mpa, yield strength: ≥ 70Mpa, elongation of 12-17%

aluminium 6061 sheets cut to size Performance: Tensile strength: 105-290Mpa, yielding strength of 85-240Mpa, elongation of 8-16%

3 processing performance

5052 aluminum is Al-Mg-Si series aluminum has good processing performance and good welding performance, corrosion resistance;

6061 aluminum is Al-Mg-Si series of aluminum has good processing performance, good oxidation and corrosion resistance.

-

- pre:pre:Aluminum circles grade 1060 3003 with highest quality

- Next:next:Aluminum Foil Tray

- Haomei aluminum

- haomei Aluminium Plate