-

- News Center

- Related News

-

- Painted color aluminum sheet for ropp caps

- 2015 Haomei Annual Meeting of the New Year

- The painted color alu

-

- How to judge quality of aluminium strip

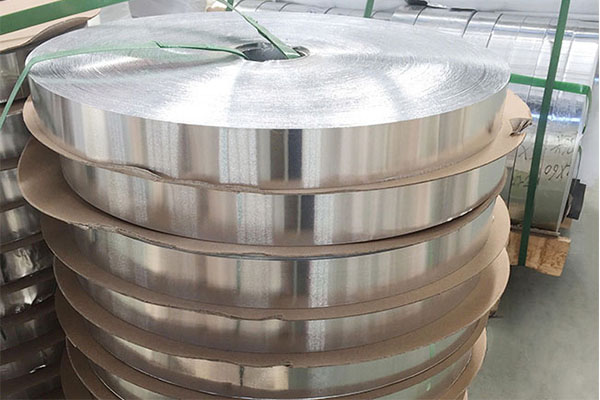

Aluminum strip is made of aluminum as the primary material and mixed with other alloying elements. It is an aluminum coil finished product obtained by embossing an aluminum ingot, and is cut into aluminum strips a desired width through a slitting machine component. With excellent reflectivity for infrared rays, ultraviolet rays, electromagnetic waves, and heat radiation, aluminum strips are primarily used for processing outstanding forming functions, high corrosion resistance and solderable parts etc. Then how to judge quality of aluminium strip in purchasing?

First, you should see if the appearance of an alloy aluminum strip is obviously distorted, whether it is smooth and flat, and whether there are other damages. It’s normal for an aluminium strip roll to be bent, but no bending marks should appear on the surface. Do not buy the aluminum strip in case of any of the above problems. Second, make sure there’s no color difference. The normal color of aluminium is natural smooth silvery. Thus no other colors are normal unless you are purchasing color coated aluminium strip rolls. In addition, oil stains are not allowed, either. Last, check whether the thickness of the aluminum strip section is the same as the type marked. For example, if you want aluminium strip 3mm, the thickness should not be less than 3mm, which is difficult to judge by naked eyes actually, thus it’s better for you to use a measuring tool.

The judgement tips above are very simple. Testing is a more complicated yet effective way. This helps you to learn composition and mechanical properties of the strip, through which you get clear whether the alloy grade, temper and rolling ways are the types you want. It entails application of specialized instruments, or extra cost for testing from a third party. However, it’s worth it since you buy aluminium strips for large quantities, and the testing fees are far less than possible losses if the quality if not satisfying.

- Haomei aluminum

- haomei Aluminium Plate