-

- News Center

- Related News

-

- Painted color aluminum sheet for ropp caps

- 2015 Haomei Annual Meeting of the New Year

- The painted color alu

-

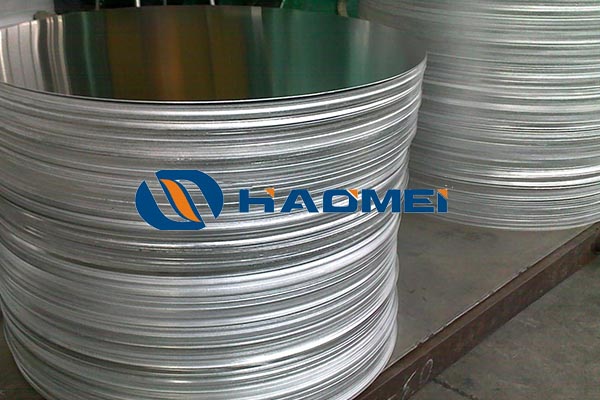

- How to judge the quality of aluminium discs circles

Aluminium discs circles are very common and widely used in our lives, such as the kitchen utensils we use, the outer casings of some household appliances, and so on. Of course, many industries now use aluminum circles as raw materials for production. So how do you judge the quality of an aluminum wafer?

To judge the quality of aluminium discs circles, we need to see its accuracy, for only those of high precision can be counted as good aluminum discs. "Everyone should know that in some electronic or aerospace industries, the accuracy of a product as an accessory is crucial, and there must be no slight error in the process of use. If the accuracy is not high, the quality of the product produced will definitely not be In addition, the quality of aluminum circles is related to the production of aluminum wafer equipment and technology. Only manufacturers of production equipment and advanced technology can produce high quality aluminum wafers. When adding aluminum wafers, it should be based on aluminum wafers. The basic requirements of processing are to produce products and strictly control quality problems. If a company is not familiar with the most basic production requirements during the development process, or to reduce the production cost of the product, deliberately steal and reduce materials during the production process. It is a fatal problem for the long-term development of the company.

It is said that many companies often produce inferior aluminium circles discs in order to obtain the small profits and ignore the benefits in the long run. This is very unfavorable for the long-term development of the company. If it is not taken seriously, it will have very serious consequences. This is a problem in the development of many aluminum wafer companies. A long-term development enterprise must eliminate these problems, which will greatly help the development of enterprises.

- Haomei aluminum

- haomei Aluminium Plate