-

- News Center

- Related News

-

- Painted color aluminum sheet for ropp caps

- 2015 Haomei Annual Meeting of the New Year

- The painted color alu

-

- Home > News > Company news >

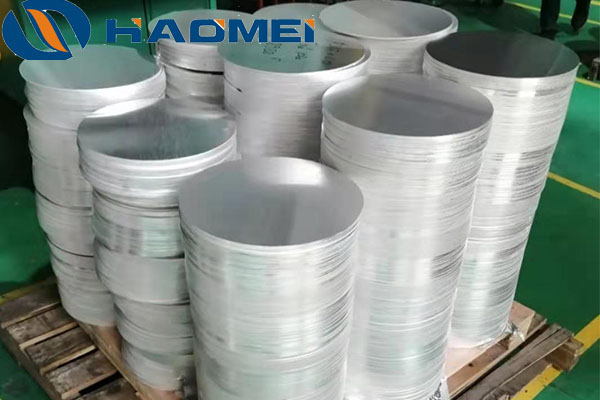

- 1060 aluminum circle for cooking utensils

1060 aluminum circle for cooking utensils can be of temper O, H12 or H14. Thickness ranges from 0.36mm to 5mm, and diameter from 120mm to 1000mm. The surface of the circle is usually mill finished, although color coating and anodizing can be customized according to per client’s practical needs. Mill finish 1060 circle discs are for ordinary cooking utensils made by processing steps of grinding, sandblasting and squeeze the lid. A pot comes into being in this way. Coated and anodized circles are processed into higher end cookware, such as pressure cookers, pizza baking pans, non-stick pan cake cookers and so on.

The specifications of our 1060 aluminum circles are complete. In addition to the conventional size, the disk with the thinnest 0.2 mm and the thickest thickness of 6.5 mm can be provided. The surface performance of the circle is so good that no obvious scratches, oil stains, oxidation or black spots appears on the surface. When the thickness of the circle is >0.5 mm, we can ensure that the edges of the finished product are neat and burr-free. We keep good control of the grain size grade and elongation of the coil in the early stage, ensuring the excellent deep drawing and spinning performance of the circle, effectively avoiding the possibility of post processing.

1060 aluminum circle, containing 99.6% aluminum composition, is also known as a pure aluminum disc. It has good elongation and tensile strength, meeting conventional processing requirements (stamping, stretching etc.) with high formability. It is also used as industrial aluminum sheet with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.1060 circle can withstand a variety of pressure processing and extension, bending. Owing to the fact that its price is lower than other grade alloy. 1060 aluminum circle for utensils is widely used in cookware, light industry and traffic signs,etc.

- Haomei aluminum

- haomei Aluminium Plate