-

- News Center

- Related News

-

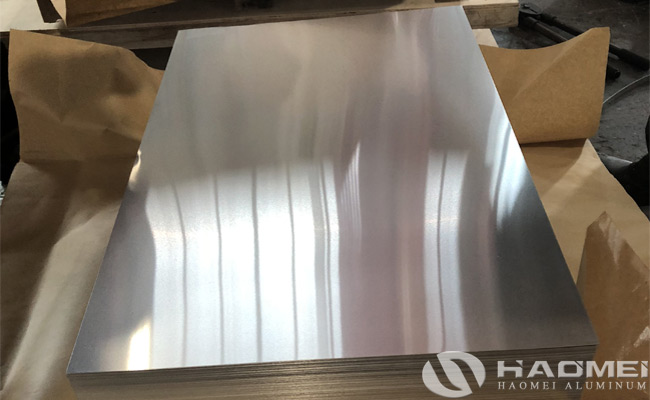

- Aluminium Plain Sheet

- 2015 Haomei Annual Meeting of the New Year

- Aluminium plain sheet

-

- Home > News > Company news >

- High Quality ASTM B209 Aluminum Plate

In modern industry, aluminum plate has become the material of choice across various sectors for its lightweight, high strength, and corrosion resistance. As a professional manufacturer deeply engaged in aluminum processing, we proudly offer high-quality aluminum plate produced in strict compliance with the ASTM B209 standard. Leveraging our internationally certified process system and comprehensive quality control, we provide comprehensive solutions for global customers in applications ranging from aerospace to architectural decoration.

The Technical Essence of the ASTM B209 Standard

ASTM B209, an internationally recognized standard for aluminum and aluminum alloy sheet, covers alloys from the 1xxx to 8xxx series and encompasses 12 core specifications, including chemical composition, mechanical properties, and surface treatment. For example, 6061-T651 alloy boasts a tensile strength of 310 MPa, a yield strength of 276 MPa, and an elongation of 8%, providing both structural rigidity and fatigue resistance. Our production line strictly adheres to the requirements of ASTM B209-14, using direct-emission spectrometers to test elements such as Si and Mg at the ppm level to ensure chemical composition deviations within ±0.01%. In terms of mechanical properties, our 2024-T351 aluminum sheet undergoes a pre-stretching process, reducing internal stress by over 90% and achieving a flatness of ±0.05mm/m, far exceeding the industry average. This high-precision feature makes it the material of choice for precision applications such as aerospace fixtures and fixtures and semiconductor device substrates.

Full-Process Quality Control System

- Raw Material Traceability

We use imported electrolytic aluminum ingots, and a pre-furnace rapid analysis system monitors impurity levels in real time to ensure Fe ≤ 0.35% and Cu ≤ 0.10% (using 5052 aluminum alloy as an example). Each batch of raw materials is accompanied by an SGS test report, ensuring full traceability from mine to final product.

- Intelligent Production Process

We have introduced a 2800mm hot rolling line from SMS Germany. Using AI algorithms to optimize rolling parameters, we achieve a thickness tolerance of ±0.03mm. A fully automated aging furnace is used for heat treatment, and the grain size of our 6061-T6 aluminum plate products is controlled to ASTM Grade 8 or above, ensuring stable mechanical properties.

- Multi-Dimensional Inspection System

Non-destructive Testing: Equipped with GE ultrasonic testing equipment from the United States, each sheet is scanned 100% of the time, with a defect detection rate exceeding 0.3mm.

Surface Treatment: Anodizing produces a film thickness of 15-25μm, and the product withstands over 1,000 hours of salt spray testing with no corrosion.

Dimensional Accuracy: Laser thickness gauges monitor the product in real time, ensuring a width tolerance of ±0.5mm and a length tolerance of ±1.0mm.

Diverse Application Solutions

High-quality ASTM B209 aluminium plate, with its excellent performance, demonstrates broad application prospects in a variety of fields:

- New Energy Vehicles:

Lightweight Body: Aluminum plate is used in the body structure, effectively reducing vehicle weight and improving energy efficiency and range.

Battery Housing Protection: Aluminum is used in the battery housing, providing robust protection for the battery while reducing the vehicle's overall weight.

Lightweight Wheels: Aluminum wheels are lightweight, contributing to improved fuel efficiency.

High-Efficiency Heat Exchangers: Aluminum plate is used in the heat exchangers of new energy vehicles, effectively managing the temperature of the battery and other components to ensure proper vehicle operation. Aerospace:

High-strength structural parts: For example, 2024-T351 alloy is used in aircraft wing spars, boasting a tensile strength of up to 425 MPa and low-temperature resistance of -200°C, ensuring flight safety.

Lightweight design: The lightweight properties of aluminium plate help reduce the weight of aircraft, improving payload capacity and fuel efficiency.

- Electronic equipment:

High conductivity and heat dissipation: For example, 1100-H14 aluminum plate is used in 5G base station heat sinks, with an electrical conductivity of ≥58% IACS, effectively dissipating heat generated during operation.

Precision housing manufacturing: Aluminum plate is used in the housings of electronic devices such as laptops, mobile phones, and cameras, combining aesthetics with protective properties.

- Architectural:

Decoration and protection: Aluminium plate is used for decorative and protective applications on building exterior walls and roofs, offering corrosion resistance, aesthetics, and enhanced building quality and durability.

Lightweight structure: The use of aluminum plate in building structures helps achieve lightweight design and improve building safety and stability.

From Boeing fuselage skins to skyscraper curtain walls, ASTM B209 aluminum plate is driving global industrial progress with its superior performance. As a leader in China's aluminum fabrication industry, we consistently strive for "zero defects." Through continuous technological innovation and rigorous quality control, we provide customers with products and services that exceed their expectations. Contact us today for customized material solutions and collaborate with us to create a green, intelligent manufacturing future.-

- pre:pre:High Quality Aluminum Circle For Utensils

- Next:next:Aluminium Plain Sheet

- Haomei aluminum

- haomei Aluminium Plate