-

- News Center

- Related News

-

- Painted Aluminum Sheet Metal

- 2015 Haomei Annual Meeting of the New Year

- Painted aluminum shee

-

- Home > News > Company news >

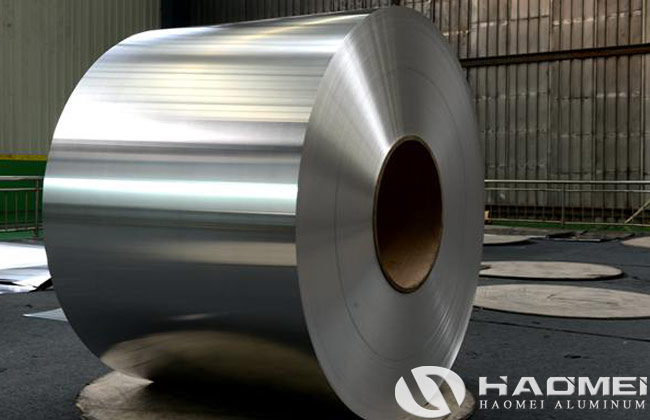

- Aluminium 3003 Coil

Aluminium 3003 coil has very good corrosion resistance, close to the corrosion resistance of industrially produced pure aluminum. 3003 aluminium coil has excellent corrosion resistance to air, water, sea surface, food, organic matter, gasoline for vehicles, neutralized carbonate solution, etc. It has good corrosion resistance in dilute alkali. 3003 aluminum coil is also known as anti-rust aluminum coil, it is commonly used in outdoor, such as pipe outsourcing, aluminum veneer, aluminum composite panel, metal roof, curtain wall and other external environments.

The performance of aluminium 3003 coil is in the condition of cold deformation, 3003 aluminum alloy has a tendency to fall off and etch, and the greater the deformation, the more serious the fall off. Because of the uneven color after anodizing treatment, anodizing treatment is generally not carried out. 3003 aluminum coils are often used in wet and cold natural environments such as outer packaging boxes, mechanical parts, refrigerators, and central air-conditioning ventilation ducts. This aluminium coil product has excellent anti-rust treatment capabilities. 3003 aluminum coil is regards as the typical product of aluminum coil series, this product is welcomed on the market.

Under normal circumstances, we like to compare aluminium 3003 coil with 1060 aluminum coils, because most of the 1000 series and 3000 series aluminum coils are mainly engaged in veneer or exterior wall construction, so we usually like to compare the two. By comparison, it is not difficult to find that the strength of 3003 aluminum coil is about 10%-20% higher than that of 1100 aluminum coil and 1060 aluminum coil. In particular, the 3003 aluminum coil with manganese alloy is better than the 1000 series in solvent resistance, corrosion resistance and formability. Of course, the price of 3003 aluminum coil us also higher than 1060 aluminum coil and 1100 aluminum coil.-

- pre:pre:Aluminium Precision Plate

- Next:next:Painted Aluminum Sheet Metal

- Haomei aluminum

- haomei Aluminium Plate