-

- News Center

- Related News

-

- High Quality Aluminum Circle For Utensils

- 2015 Haomei Annual Meeting of the New Year

- High-quality aluminum

-

- Home > News > Company news >

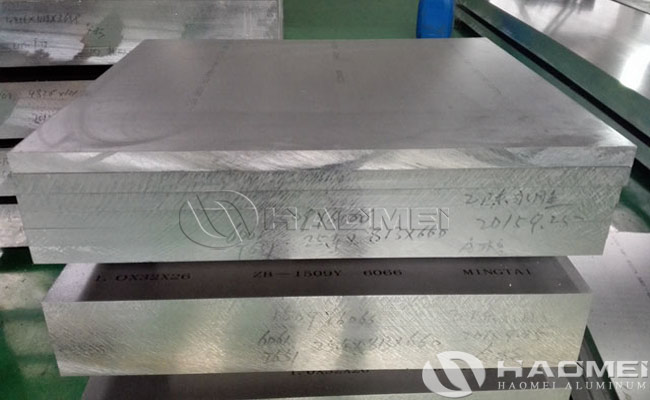

- Aluminium Square Plate

Square aluminum plate is a rectangular plate made of aluminum alloy as the base material, formed by rolling or processing. Due to its regular shape, light weight and durability, it is widely used in architectural decoration, industrial manufacturing and other fields.

Classification and specifications of aluminium square plate:

1. By alloy composition

- Pure aluminum square plate: such as 1050, 1060 and 1100 series, with high purity and good corrosion resistance, suitable for scenes with low strength requirements.

- Alloy aluminum square plate: such as 3003, 5052, 6061 series, by adding copper, magnesium, manganese and other elements to enhance strength and hardness, suitable for complex structures or scenes with high strength requirements.

2. By thickness

Thin plate: 0.15-2.0mm, commonly used in lightweight scenes such as suspended ceilings and light troughs.

Conventional plate: 2.0-6.0mm, suitable for conventional decoration such as walls and ceilings.

Thick plate: 6.0-200mm, used for heavy structures or special engineering needs.

3. Surface treatment

- Color coating: Fluorocarbon paint, powder spraying (such as powder-coated aluminum plate) to improve aesthetics and weather resistance.

- Wood grain treatment: Through thermal transfer or corrosion process, imitate natural wood grain.

- Anodizing: Electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

- Brushing: mechanical finishing process that involves using an abrasive material to create a textured surface.

4. Common sizes

Standard size: 600×600mm, 300×300mm, can also be customized according to needs.

Main uses of aluminium square plate:

1. Architectural decoration

- Ceiling: Square aluminum gusset plates are widely used in kitchens, bathrooms, shopping malls and other spaces, with ventilation and sound absorption functions.

- Walls and background walls: Wood grain and porcelain aluminum plates are used in hotels, hospitals, subway stations and other places, combining beauty and durability.

- Column and beam wrapping: Square sealed aluminum plates are used for column and beam decoration to improve overall coordination.

2. Industry and transportation

- Railway transportation: used for vehicle body connectors, seats, advertising stands, etc.

- New energy vehicles: lightweight vehicle body parts, reducing energy consumption.

- Photovoltaic brackets: corrosion-resistant, high-strength aluminum alloy brackets.

3. Other scenarios

- Household appliances: refrigerator and microwave oven shells.

- Aerospace: high-strength aluminum alloys are used for aircraft skins and spacecraft structures.

- Furniture and cabinets: modern style surface decoration.

Advantages of aluminum square plate are:

- Lightweight and high strength: low density (2.7g/cm³), strength close to that of steel.

- Corrosion resistance: surface oxide film or coating resists acid and alkali environments.

- Easy to process: can be bent, stamped, and welded into complex shapes.

- Environmentally friendly and recyclable: recycling rate reaches over 95%.

- Haomei aluminum

- haomei Aluminium Plate