-

- News Center

- Related News

-

- Home > News > Company news >

- Aluminum Brazing Sheet For Evaporator Fin

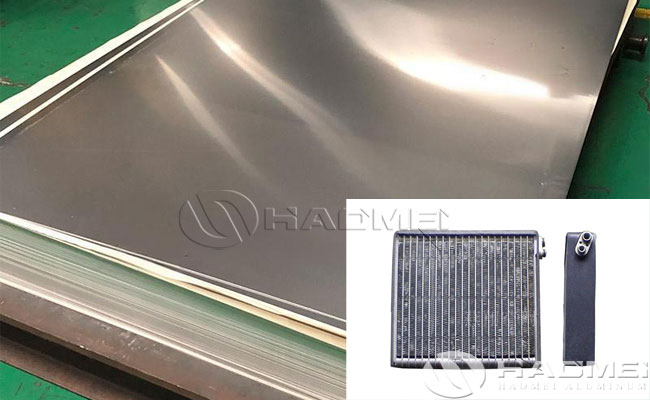

Aluminum brazing sheet for evaporator fins is a multi-layer composite metal material widely used in refrigeration equipment, the automotive industry, and other fields. It features efficient heat transfer, compact structure, and corrosion resistance.

Material Composition of aluminum brazing sheet for evaporator fin:

Aluminum brazing sheet typically consists of a core layer and a cladding layer. The core layer utilizes an aluminum alloy with excellent strength and processability, such as 3003 aluminum sheet. Its primary chemical composition, by weight, consists of 0.06-1.5% Mn and 1.2-4.0% Cu, with the remainder primarily consisting of aluminum and impurities. The cladding layer utilizes an Al-Si-based filler alloy, such as 4045 or 4343 aluminum sheet, adhered to one or both sides of the core layer to form a composite sheet. This structural design ensures both overall material strength and excellent brazing performance. The alloy layer cladding process combines the core aluminum alloy and the cladding filler alloy through rolling and lamination processes to form a multi-layer composite metal material.

Performance advantages of aluminum brazing sheet for evaporator fin:

- Efficient heat transfer:

Aluminum brazing sheet has excellent thermal conductivity, enabling rapid heat transfer from the evaporator interior to the external environment. Its fin design significantly increases the heat dissipation area, increasing it several times or even dozens of times compared to a bare tube evaporator, significantly improving the evaporator's heat transfer efficiency.

- Compact structure:

The aluminum brazing plate evaporator features a flat, thin, and compact design. This compact design allows the evaporator to achieve powerful heat transfer within a limited space, making it particularly suitable for space-constrained equipment such as air conditioner indoor units and refrigerators.

- High corrosion resistance:

The aluminum brazing sheet surface undergoes special treatments, such as anodizing, to form a dense oxide film that effectively resists corrosion. Furthermore, aluminum itself possesses excellent corrosion resistance, enabling stable operation in harsh environments such as humidity and corrosive gases.

- Lightweight:

Aluminum's low density allows the use of aluminum brazing sheet to reduce the overall weight of the equipment, making it easier to install and transport.

- Processability:

Aluminum brazing plate is easy to process and can be manufactured into a variety of shapes and sizes to suit different applications.

- Brazelability:

Aluminum brazing sheet undergoes special treatments, allowing it to be joined to other aluminum materials or alloys through brazing to form a stable structure.

Application areas of aluminum brazing cladding sheet for evaporator fin:

- Refrigeration equipment:

Aluminum brazing plate evaporators are widely used in refrigeration equipment, including household and commercial air conditioners, cold storage, and other applications. Their efficient heat transfer and compact structure enable refrigeration equipment to quickly reach the set temperature while saving installation space.

- Automotive industry:

Aluminum brazing plate evaporators also play a vital role in automotive air conditioning systems. Their lightweight, corrosion-resistant, and efficient heat transfer properties make automotive air conditioning systems more energy-efficient, environmentally friendly, and reliable.

- Other Applications:

Aluminum brazing sheet can also be used in heat exchange equipment, such as oxygen generators and heat exchangers, meeting the needs of diverse applications for efficient heat transfer and corrosion resistance.

- Haomei aluminum

- haomei Aluminium Plate