-

- News Center

- Related News

-

- Mic 6 Aluminum Tooling Plate

- 2015 Haomei Annual Meeting of the New Year

- MIC 6 is a commonly u

-

- Home > News > Company news >

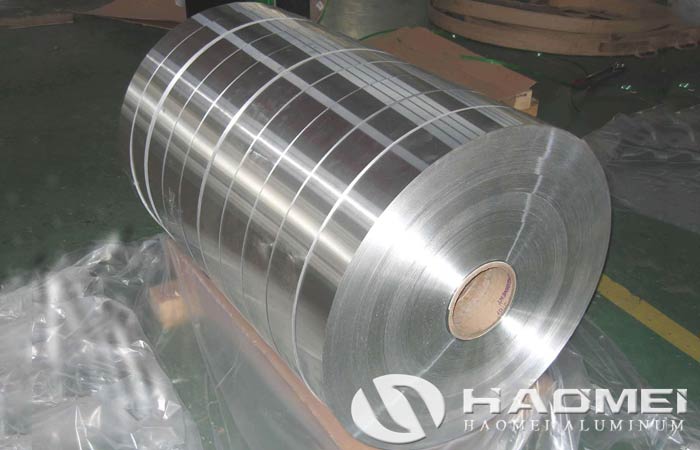

- Copolymer Coated Aluminium Tape

Copolymer coated aluminium tape is a composite material composed of aluminum tape and a polymer coating. It combines the excellent properties of aluminum with the characteristics of polymers and is widely used in various fields.

Structure and Composition

- Aluminum tape base material: Typically made of aluminum alloys such as 1050, 1060, 1200, 1145, and 8011, the thickness of the aluminum tape generally ranges from 0.10mm to 0.3mm.

- Copolymer coating: Common coating materials include ethylene acrylic acid copolymer (EAA), polyethylene (PE), and polyethylene terephthalate (PET), with coating thicknesses generally ranging from 0.03mm to 0.08mm.

Features of Copolymer Coated Aluminium Tape:

- Excellent shielding performance:

Aluminum tape offers excellent electrical conductivity and electromagnetic shielding properties, effectively shielding against electromagnetic interference and preventing signal leakage. It is commonly used in cable shielding.

- Moisture and water resistance:

The copolymer coating prevents moisture penetration, making the aluminum tape highly moisture-resistant and water-resistant, protecting internal contents from moisture deterioration. It is suitable for applications requiring moisture-proof protection, such as cables and packaging.

- Corrosion Resistance:

Aluminum inherently possesses a certain degree of corrosion resistance. The added protection of a polymer coating further enhances its resistance to chemicals like acids and alkalis, extending its service life.

- Flexibility and Processability:

The copolymer coating imparts flexibility to the aluminum tape, making it easy to bend, wind, and shape, adapting to various application scenarios.

- Strong Adhesion:

The copolymer coating maintains excellent adhesion to the aluminium strip, preventing the coating from easily detaching during use and ensuring stable material performance.

- Wear Resistance:

The coating enhances the aluminum tape's wear resistance, making it suitable for use in environments subject to frequent friction or contact.

- Aesthetics:

Copolymer coatings are available in a variety of colors and gloss levels, enhancing the ribbon's aesthetic appeal and meeting diverse design requirements.

- Insulation:

Some copolymer coatings exhibit excellent electrical insulation properties, making them suitable for use in electronic and electrical equipment.

- Cleanability:

The coated surface is typically smooth, making it easy to clean and maintain.

Preparation Methods of Copolymer Coated Aluminum Tape:

The main methods include collinear stretching and copolymer coating. The collinear stretching method involves stretching aluminum tape and polymer film together, interweaving them at the microscopic level and forming a strong bond. The copolymer coating method involves coating the aluminum tape with a layer of polymer, which is then dried and cured to form a strong bond with the aluminum tape.

Core Performance Parameters and Testing Standards

- Shielding Performance

The shielding effectiveness (SE) against electromagnetic waves must comply with GB/T 12190-2006, with an SE of ≥80dB at frequencies of 100MHz-1GHz (applicable to communication cables).

Conductive Performance: The volume resistivity of the coated aluminum tape is tested, generally requiring ≤1.5×10⁻⁸Ω·m (to ensure shielding continuity).

- Environmental Resistance

Salt Spray Resistance Test: According to ASTM B117, spraying in a 5% NaCl solution for 500 hours requires no blistering or flaking of the coating, and corrosion of the aluminum tape is ≤5%. Moisture and Heat Resistance Test: Coating adhesion loss ≤ 10% after 1000 hours in an environment of 40°C and 90% relative humidity.

- Mechanical Properties

Flexibility: Coating shows no cracks after a 180° bend test (diameter twice the thickness of the aluminum strip) (GB/T 1731-1993).

Impact Resistance: Coating shows no peeling after impact with a 0.5kg hammer from a height of 50cm (ASTM D2794).

Applications of Copolymer Coated Aluminium Tape:

- Cable Industry:

It is an important material for cable shielding and moisture protection. It can be used in communication cables, power cables, fiber optic cables, submarine cables, etc., effectively protecting the conductors within the cables and improving their performance and service life.

- Construction Industry:

It can be used as a thermal and sound insulation material in walls, roofs, and floors to improve the thermal insulation and soundproofing of buildings.

- Packaging Industry:

It is used in packaging for food, pharmaceuticals, and other industries, leveraging its moisture and corrosion resistance to ensure product quality and safety.-

- pre:pre:Aluminium Plain Sheet

- Next:next:Mic 6 Aluminum Tooling Plate

- Haomei aluminum

- haomei Aluminium Plate