-

- News Center

- Related News

-

- 4045/3003/4045 Aluminum Brazing Sheet

- 2015 Haomei Annual Meeting of the New Year

- 4045/3003/4045 alumin

-

- Home > News > Company news >

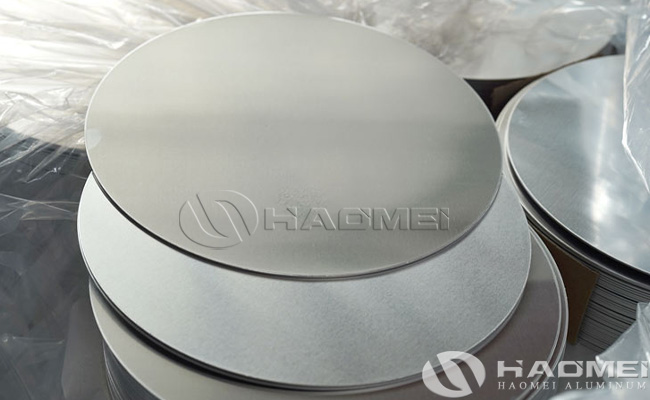

- Soft Aluminum Circle O Temper

O temper soft aluminum circles are highly ductile aluminum products that have undergone a complete annealing process. The core characteristic is that they achieve their softest state by eliminating internal stress, making them suitable for complex forming processes such as deep drawing and spinning. The O temper (Annealed) represents the annealed state, the aluminum circle material undergoes a slow cooling treatment at 340-400°C, allowing for full grain recovery. This results in the lowest strength but the highest ductility. For example, common 1060 pure aluminum, with an aluminum content of ≥99.6%, has an O-state tensile strength of only 60-95 MPa, but an elongation of over 30%, making it easily adaptable to deep drawing and spinning processes.

Production Process of Soft Aluminum Circle:

- Cold-rolled aluminum circles:

They offer high surface flatness and are suitable for small to medium diameter electronic components (10-100mm). However, they are prone to developing orange peel texture during deep drawing.

- Hot-rolled aluminum circles:

Stamped from hot-rolled billets, they offer superior tensile strength and lack noticeable wrinkles. They are often used for large products (over 500mm in diameter) such as kitchenware and lamps, but they are more expensive.

Specification of Soft Aluminium Circle:

Thickness Range: 0.3mm-10mm.

Common diameters: Range from 100mm to 1200mm.

Common Alloy Grades of Soft Aluminum Circle:

- 1060 Aluminum Circle

Al ≥99.6%), with good conductivity, low cost Lighting, suitable for household cookware.

- 3003 Aluminum Circle

Contains 1.2% manganese (Mn), with high corrosion resistance,suitable for cookware and battery casings.

- 5052 Aluminum Circle

Contains 2.5% magnesium (Mg) + 0.25% chromium (Cr), with high strength + corrosion resistance, suitable for radiators and automotive parts.

- 1100 Pure Aluminum Circle

Al≥99.0%, with excellent plasticity, suitable for packaging and decorative parts.

Key Properties of Soft Aluminium Circle:

- High plasticity:

Elongation >15%, allowing for cold working such as large-angle bending, deep drawing, and spinning without cracking.

- Low strength:

Low tensile strength (typically <120 MPa), suitable for applications requiring deformation.

- Surface properties:

Forms a dense oxide film, offering strong corrosion resistance, with no noticeable corrosion after a salt spray test of >240 hours.

- Thermal and Electrical Conductivity:

Thermal conductivity 200-230 W/(m·K), electrical conductivity ≥35% IACS, 30%-40% better than copper.

Comparison O Temper with Other Properties:

H24: Work-hardened and incompletely annealed, it offers high hardness (tensile strength 180-350 MPa), making it suitable for applications requiring strength, such as pipe insulation.

O temper, soft aluminum circles, due to their plasticity, are widely used in the following industries:

- Cookware Industry:

Non-stick pans and pressure cookers: 3003 alloy aluminum circles offer strong corrosion resistance, meeting the requirements of acidic environments.

Rice cooker liners and smokeless pots: 5052 aluminum alloy offers high strength and thermal conductivity, making it suitable for high-power equipment.

Aluminum Kettles and Basins: 1060/1070 pure aluminum circles series offers low cost and is suitable for everyday use.

- Lighting and Electronics:

Lampshades and lamps: The plasticity of O temper allows for complex shape designs, such as spinning of cylindrical parts.

Radiator Base: 5052 alloy offers excellent thermal conductivity and is used for heat dissipation in electronic devices.

- Packaging and Construction:

Road signs and aluminum containers: Corrosion resistance extends outdoor service life.

Insulation: Aluminum circles, after being stamped and bent, are used for pipe insulation.

- Industry and Transportation:

Battery Housing: 3003 aluminum alloy's corrosion resistance meets the requirements of battery acid electrolytes.

Automotive Parts: Lightweight features, such as wheels and body panels, reduce energy consumption.-

- pre:pre:Mic 6 Aluminum Tooling Plate

- Next:next:4045/3003/4045 Aluminum Brazing Sheet

- Haomei aluminum

- haomei Aluminium Plate